We can meet very different needs. We can use signal control, normally intended for a foot switch, which allows you to control the laser beam. We can use this for many applications, including controlling the closing of doors or other security systems to maintain work safety.

For example, until the curtain, door or element protecting the workplace is closed, the laser beam will not be released. When the contact is closed, when the curtain has been closed, we can work with the device. This allows in open places, e.g. in a hall, to properly secure the workplace of the device. The main goal is to protect the eyes from accidental reflection of the beam, in particular when marking objects and metal parts, especially shiny ones, which can reflect the beam.

-

19,90€ – 39,90€ excl. tax Select options This product has multiple variants. The options may be chosen on the product page

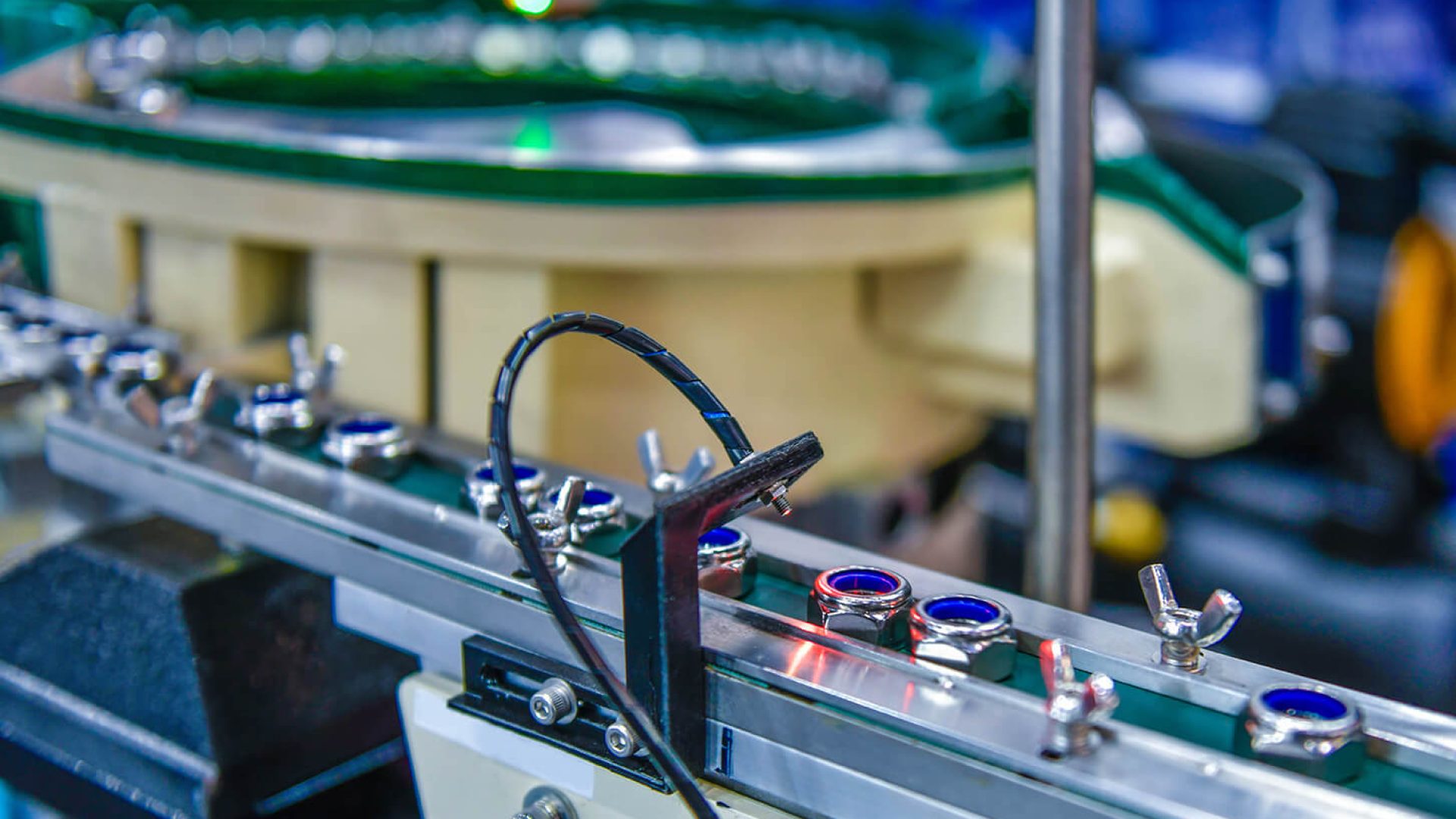

Due to the fact that we can also place the device using its modularity, a small housing that can be easily attached to the side, under or above the production line, and to the length of the optical fiber, place the head with the lens in a different place. An example of such a solution is marking the date and batch number of the product on tubes. The housing was attached to the side of the machine on aluminum profiles. A touch tablet was added to the device for control, and the head itself was placed in front of the rotary system of the tube filling and crimping machine. After filling the tube, the device moves it in front of the head with the laser.

A sensor has been added to the device, thanks to which the laser recognizes whether or not there is a tube in the field with it. The sensor itself uses the PS connector of the footswitch to automatically trigger the beam. When the object is found and the sensor is activated, the laser triggers a beam with a set sequence of characters, marking the tube. This is one example of the use and possibilities of connecting the sensor to the EM-Smart laser and the freedom in its installation, thanks to its small dimensions and modular design.