The basic product that speeds up and partially automates work on our laser is the foot switch.

The foot switch is a simple device that, when operated by foot, frees our hands and allows us to speed up the repetitive actions of placing the marked object under the laser head. The appropriate settings for the button function and beam release repeatability are located in the software included with the EM-Smart laser.

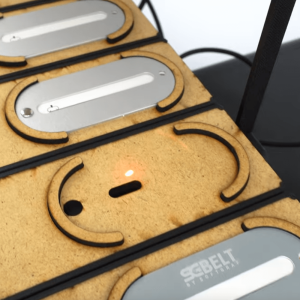

The second automation element is the automatic beam release sensor. The sensor sends a beam of light towards the photoresistor. If there is no gap between these two elements, the laser does not work, but if the beam is interrupted by the inserted marking object, the laser generates a beam. This simple sensor can be used in many places and automate the marking process, e.g. on production lines.

SGBelt belt feeder

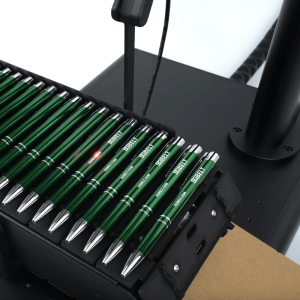

The third product that makes work easier is a belt feeder that can be mounted on the EM-Smart laser work area. This simple device allows you to speed up the marking of large quantities of similar elements. The proposed solution is based not only on a simple but also innovative solution, which is that the slots on which we place the items can be easily replaced and adapted to various applications. This is not a simple conveyor with a belt and a camera mounted that reads the shape, because it is difficult to mark rounded objects that can move on such a feeder. The presented product has adapted slots for marked objects, which can be milling cutters, drills, pens, but also short tubes, bearings, small nameplates, medals, key rings, tools, including specialist ones, and many other items for which the 150x150mm laser work area is sufficient to mark them.

In addition, the software included with the laser allows for cooperation with databases, so we do not have to mark only one element, e.g. a logotype, but a series of changing data, these can be serial numbers, production date, any description or automatically generated QR code or data matrix. The travel time is adjusted to the amount of information being marked, and additionally secured with the previously described sensor, which will prevent marking when there is no item in the prepared slot.

Summary

If you do not have the ability to customize the marked item in your company, send it to us and we will customize the socket accordingly. Then, depending on the possibilities, we will send you a design for self-printing or prepare a set of sockets and send them to you by courier. Check the cost of design and printing most typical sockets!