To start with, we provide 4 different sockets to choose from.

- straight, double socket for marking nameplates or business cards and flat tools;

- single slot with double pen marking holders;

- single universal socket with replaceable inserts – the fastest way to retool the socket, you can change the purpose of the feeder in 2 minutes;

- straight slot for marking nameplates, business cards and other flat objects

To fill the feeder with sockets, we have 2 types of sockets for correct design, single and double. Whether the socket is dedicated to the item or universal is determined by the shape and geometry of the item to be marked. Accessories for universal sockets (inserts) are the easiest element to design, for this we only need a vector graphics program! Their exceptionally fast method of replacement, causes exceptional functionality of the SGBELT feeder and allows marking even small series of products.

Single Socket – What to Remember

When creating a single socket during the design process, you should remember a few things. The most important thing is to reproduce the correct dimensions of the socket. In our knowledge base, you will find a separate article “How to design a universal socket”, where we describe exactly how to do it yourself. Another important detail during the design process is the correct location of the central cutout for the sensor, which checks whether an item has been placed in the socket or not. For universal sockets, we have also planned a design of replaceable inserts, thanks to which you can quickly change the item for marking.

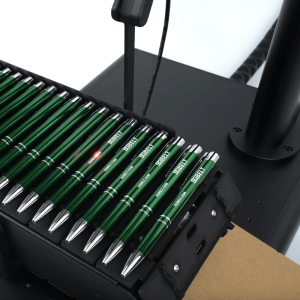

Based on the 3D design of the item, we can design any mounting bracket for the socket, in which you will place the item for marking in the appropriate position. Additionally, the single socket can be divided into 2 working sockets, depending on the dimensions of the item, as in the case of pens. The consequence of this is the appropriate setting of the feeder steps in its panel and obtaining exceptional efficiency, this may apply, for example, to marking drills, milling cutters, tools with a diameter of up to 12 mm.

Double Socket – How to Design

When creating a double socket, you must first assume the correct dimensions of the socket. Here, too, we have an article in the knowledge base on how to do it exactly. Similarly to the case of a single socket, it is important to correctly position the cutout for the sensor. While maintaining the basic dimensions, we can design any handle, insert in the socket for the item of interest to us. As standard, we provide a socket that facilitates marking, e.g. nameplates, and a universal socket with replaceable inserts.

Laser marking with SGBELT feeder

In the video we showed marking of many different items on single and double nests with replaceable inserts, which speed up changing nests for new applications and marking of subsequent items. Marking speed depends on the power of the used laser. The speed of the feeder can be easily adjusted for marking with high-power lasers, using the high speed of the feeder. Easy control, possibility of changing the language, 3 settings for nests: single, double and single with two handles. All in a few simple steps available directly from the feeder menu.

100% repeatability

Thanks to digital micro-calibration in the controller you achieve complete repeatability.

Minimizing errors

The sensor will read whether there is an object placed on the plate; if there is not, it will not trigger the laser beam.

Speed of action

Up to 120 cycles per minute, the speed depends solely on how long the laser takes to mark.

Ease of use

Built-in national language, clear instructions and step-by-step video on how to set up the device and connect the laser.

Expandable

When creating the feeder, we knew that the needs, even of serial production, change. So change the feeder to new challenges using design and 3D printing.

Wide range of applications

Thanks to the possibility of quick changes of mounting sockets, the number of industries where this device is used for serial marking of small items has increased.

The most important benefits of using replaceable sockets

- 3 speed variants for feeder sockets (x1/2; x1; x2).

- An infinite number of socket designs.

- Full availability of socket implementation on a 3D printer.

- Universal sockets with replaceable inserts from a 3D printer or cut with a CO2, diode or milling laser.

- High flexibility allows for the implementation of even small series.

- Quick return on investment thanks to acceleration and automation of work.

These are just some of the selected features of the SGBELT feeder application. It is worth reviewing more materials to see that the SGBELT feeder is a good return on investment.

Summary

You can choose the device with one of our proposed sockets or order two selected or all types of sockets. Universal sockets are sold without inserts, the insert must be cut out, which can also be ordered during order fulfillment. Remember to send a project with a cutting line adapted to the item that will be marked on the insert.

In the knowledge base you will also find an article on how to prepare the insert using a laser.

We also leave the user complete freedom to design the socket they need and print it on a 3D printer or the insert and cut it out.

This flexibility allows the feeder to be used in education and by all creative people who want to expand their workshop to include serial marking.